We continue exploring the endless possibilities on the MicroML (Machine Learning for Microcontrollers) framework on Arduino and ESP32 boards: in this post we're back to image classification. In particular, we'll distinguish handwritten digits using an ESP32 camera.

If this is the first time you're reading my blog, you may have missed that I'm on a journey to push the limits of Machine learning on embedded devices like the Arduino boards and ESP32.

I started with accelerometer data classification, then did Wifi indoor positioning as a proof of concept.

In the last weeks, though, I undertook a more difficult path that is image classification.

Image classification is where Convolutional Neural Networks really shine, but I'm here to question this settlement and demostrate that it is possible to come up with much lighter alternatives.

In this post we continue with the examples, replicating a "benchmark" dataset in Machine learning: the handwritten digits classification.

The task

The objective of this example is to be able to tell what an handwritten digit is, taking as input a photo from the ESP32 camera.

In particular, we have 3 handwritten numbers and the task of our model will be to distinguish which image is what number.

I only have a single image per digit, but you're free to draw as many samples as you like: it should help improve the performance of you're classifier.

1. Feature extraction

When dealing with images, if you use a CNN this step is often overlooked: CNNs are made on purpose to handle raw pixel values, so you just throw the image in and it is handled properly.

When using other types of classifiers, it could help add a bit of feature engineering to help the classifier doing its job and achieve high accuracy.

But not this time.

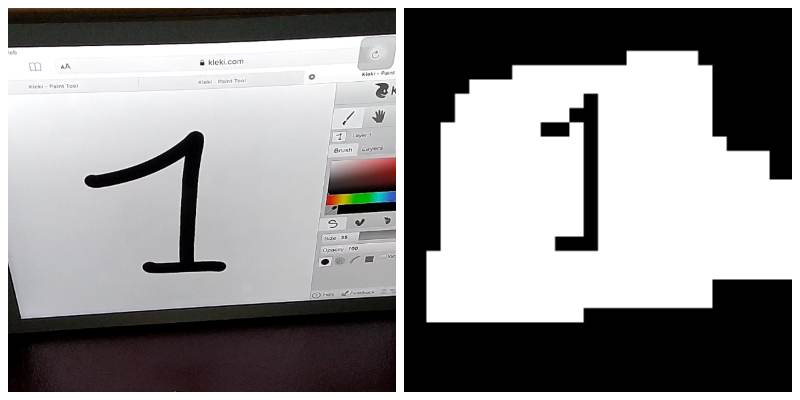

I wanted to be as "light" as possible in this demo, so I only took a couple steps during the feature acquisition:

- use a grayscale image

- downsample to a manageable size

- convert it to black/white with a threshold

I would hardly call this feature engineering.

This is an example of the result of this pipeline.

The code for this pipeline is really simple and is almost the same from the example on motion detection.

#include "esp_camera.h"

#define PWDN_GPIO_NUM -1

#define RESET_GPIO_NUM 15

#define XCLK_GPIO_NUM 27

#define SIOD_GPIO_NUM 22

#define SIOC_GPIO_NUM 23

#define Y9_GPIO_NUM 19

#define Y8_GPIO_NUM 36

#define Y7_GPIO_NUM 18

#define Y6_GPIO_NUM 39

#define Y5_GPIO_NUM 5

#define Y4_GPIO_NUM 34

#define Y3_GPIO_NUM 35

#define Y2_GPIO_NUM 32

#define VSYNC_GPIO_NUM 25

#define HREF_GPIO_NUM 26

#define PCLK_GPIO_NUM 21

#define FRAME_SIZE FRAMESIZE_QQVGA

#define WIDTH 160

#define HEIGHT 120

#define BLOCK_SIZE 5

#define W (WIDTH / BLOCK_SIZE)

#define H (HEIGHT / BLOCK_SIZE)

#define THRESHOLD 127

double features[H*W] = { 0 };

void setup() {

Serial.begin(115200);

Serial.println(setup_camera(FRAME_SIZE) ? "OK" : "ERR INIT");

delay(3000);

}

void loop() {

if (!capture_still()) {

Serial.println("Failed capture");

delay(2000);

return;

}

print_features();

delay(3000);

}

bool setup_camera(framesize_t frameSize) {

camera_config_t config;

config.ledc_channel = LEDC_CHANNEL_0;

config.ledc_timer = LEDC_TIMER_0;

config.pin_d0 = Y2_GPIO_NUM;

config.pin_d1 = Y3_GPIO_NUM;

config.pin_d2 = Y4_GPIO_NUM;

config.pin_d3 = Y5_GPIO_NUM;

config.pin_d4 = Y6_GPIO_NUM;

config.pin_d5 = Y7_GPIO_NUM;

config.pin_d6 = Y8_GPIO_NUM;

config.pin_d7 = Y9_GPIO_NUM;

config.pin_xclk = XCLK_GPIO_NUM;

config.pin_pclk = PCLK_GPIO_NUM;

config.pin_vsync = VSYNC_GPIO_NUM;

config.pin_href = HREF_GPIO_NUM;

config.pin_sscb_sda = SIOD_GPIO_NUM;

config.pin_sscb_scl = SIOC_GPIO_NUM;

config.pin_pwdn = PWDN_GPIO_NUM;

config.pin_reset = RESET_GPIO_NUM;

config.xclk_freq_hz = 20000000;

config.pixel_format = PIXFORMAT_GRAYSCALE;

config.frame_size = frameSize;

config.jpeg_quality = 12;

config.fb_count = 1;

bool ok = esp_camera_init(&config) == ESP_OK;

sensor_t *sensor = esp_camera_sensor_get();

sensor->set_framesize(sensor, frameSize);

return ok;

}

bool capture_still() {

camera_fb_t *frame = esp_camera_fb_get();

if (!frame)

return false;

// reset all the features

for (size_t i = 0; i < H * W; i++)

features[i] = 0;

// for each pixel, compute the position in the downsampled image

for (size_t i = 0; i < frame->len; i++) {

const uint16_t x = i % WIDTH;

const uint16_t y = floor(i / WIDTH);

const uint8_t block_x = floor(x / BLOCK_SIZE);

const uint8_t block_y = floor(y / BLOCK_SIZE);

const uint16_t j = block_y * W + block_x;

features[j] += frame->buf[i];

}

// apply threshold

for (size_t i = 0; i < H * W; i++) {

features[i] = (features[i] / (BLOCK_SIZE * BLOCK_SIZE) > THRESHOLD) ? 1 : 0;

}

return true;

}

void print_features() {

for (size_t i = 0; i < H * W; i++) {

Serial.print(features[i]);

if (i != H * W - 1)

Serial.print(',');

}

Serial.println();

}2. Samples recording

To create your own dataset, you need a collection of handwritten digits.

You can do this part as you like, by using pieces of paper or a monitor. I used a tablet because it was well illuminated and I could open a bunch of tabs to keep a record of my samples.

As in the apple vs orange, keep in mind that you should be consistent during both the training phase and the inference phase.

This is why I used tape to fix my ESP32 camera to the desk and kept the tablet in the exact same position.

If you desire, you could experiment varying slightly the capturing setup during the training and see if your classifier still achieves good accuracy: this is a test I didn't make.

3. Train and export the classifier

For a detailed guide refer to the tutorial

from sklearn.ensemble import RandomForestClassifier

from micromlgen import port

# put your samples in the dataset folder

# one class per file

# one feature vector per line, in CSV format

features, classmap = load_features('dataset/')

X, y = features[:, :-1], features[:, -1]

classifier = RandomForestClassifier(n_estimators=30, max_depth=10).fit(X, y)

c_code = port(classifier, classmap=classmap)

print(c_code)At this point you have to copy the printed code and import it in your Arduino project, in a file called model.h.

4. The result

Okay, at this point you should have all the working pieces to do handwritten digit image classification on your ESP32 camera. Include your model in the sketch and run the classification.

#include "model.h"

void loop() {

if (!capture_still()) {

Serial.println("Failed capture");

delay(2000);

return;

}

Serial.print("Number: ");

Serial.println(classIdxToName(predict(features)));

delay(3000);

}Done.

You can see a demo of my results in the video below.

Project figures

My dataset is composed of 25 training samples in total and the SVM with linear kernel produced 17 support vectors.

On my M5Stick camera board, the overhead for the model is 6.8 Kb of flash and the inference takes 7ms: not that bad!

Troubleshooting

It can happen that when running micromlgen.port(clf) you get a TemplateNotFound error. To solve the problem, first of all uninstall micromlgen.

pip uninstall micromlgenThen head to Github, download the package as zip and extract the micromlgen folder into your project.

Check the full project code on Github